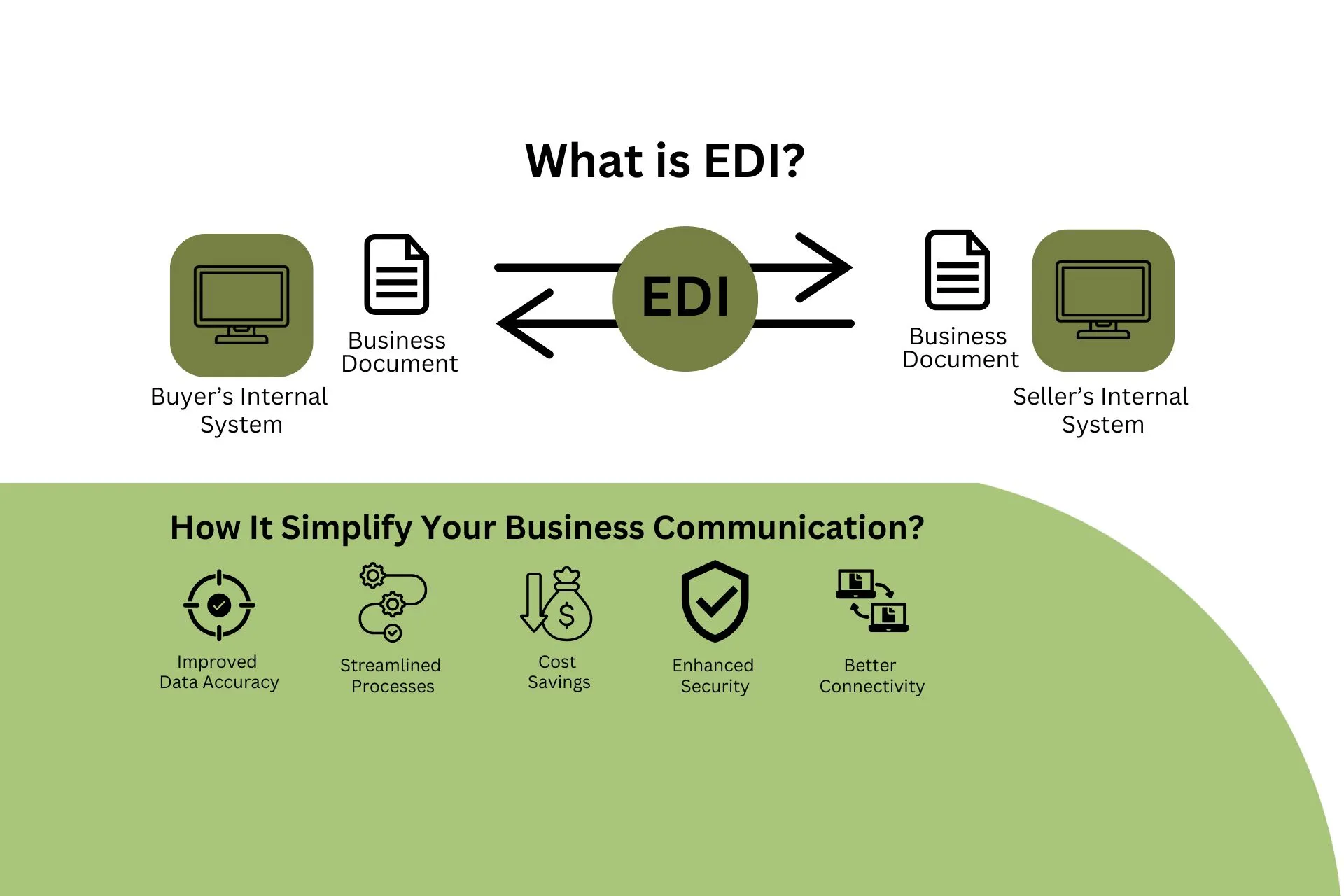

ERP (Enterprise Resource Planning) and EDI (Electronic Data Interchange) are two essential technologies that can greatly benefit businesses when used together. Any organisation that depends on an efficient supply chain must have EDI systems and ERP solutions. The ERP system manages records on the back end, whereas EDI facilitates communication with trading partners on the front end.

EDI integration can be difficult, especially if your supply chain has a lot of moving components and a lot of actors. When done effectively, it can significantly increase your visibility and productivity. However, when done incorrectly, integration devolves into a tangle of unique integrations that causes more issues than it resolves.

The Benefits of Integrating ERP with EDI

Since inception, EDI and ERP integration have been carried out separately, with each software solution managing certain business operations. Enterprises would either manually input EDI data into the ERP or haphazardly construct proprietary connectors to provide connectivity between EDI and ERP systems.

Technology improvements have made it possible for EDI solutions to interact with ERP programmes to automate the transfer of data between backend and frontend apps. Data is able to move automatically from one end to the other thanks to EDI-ERP connectivity. Your business can gain the following benefits by integrating EDI with ERP:

- Improved data accuracy by eliminating manual data entry

- Faster transactions by automating data transfers between ERP and EDI

- Enhanced supply chain visibility by enabling you to focus on your trading partners instead of trouble-shooting errors.

Different EDI Integrations Occur

Choosing whether to use your current ERP system for EDI or create a new application is crucial while going through an EDI migration. Although picking a combined ERP-EDI solution may seem like the ideal course of action, most businesses that do so eventually become dissatisfied.

Your company may run a serious risk by using EDI with the patched-on functionalities provided by ERPs like Oracle and IQMS. In favour of using a separate EDI platform to implement EDI integration.

Flexibility:

The ability to implement infrastructure changes more quickly is one of the top advantages of separating EDI and ERP systems. The capabilities of their core products, including order processing and inventory management, are improved more by ERP providers who offer EDI add-ons than the front-end EDI functionalities are. Often, adopting crucial EDI capabilities is sacrificed in favour of ERP. As a result, ERP providers typically take far longer than specialised EDI vendors to deploy changes in partner connections.

Allow HubBroker to assist with the implementation of a independent ERP-compatible EDI integration.

The easiest way to integrate ERP and EDI is to let both programmes carry out their respective tasks while interacting naturally. ERPs with basic EDI tools fall far short of the capabilities and knowledge provided by the finest EDI platforms.

Integration of the supply chain requires EDI. In order to fulfil all of its intended integration functions, a contemporary organisation needs a reliable EDI solution that integrates seamlessly with its ERP and other backend systems.

As the industry’s top supplier of EDI knowledge, HubBroker can assist you in implementing the best EDI integration and streamlining communication with your trading partners. Without the drawbacks of ERP-based EDI systems, our knowledgeable EDI professionals will assist you in automating your EDI operations.